News

-

Precision Optics Manufacturing

Precision optics manufacturing refers to the R&D, design and manufacture of high-end optical lenses and advanced optical instruments, including flat-window lenses, prisms, spherical mirrors and aspheric surfaces, customized special-shaped products and coatings, and can provide a variety of ma...Read more -

Optical System Assembly

Optical System Assembly Optical systems consist of a wide variety of products and optical components. Optical assemblies feature a variety of individual parts as well as kits to address standard laser or optical requirements such as beam manipulation, focusing, mounting and alignment. When design...Read more -

Thin Film Laser Polarizers

Thin Film Laser Polarizers As a leading manufacturer of high-precision optical components, we specialize in the production of various devices that generate or manipulate polarized light waves. Specifically, we offer a complete line of polarizer optics, including dichroic plate polarizers, cube or...Read more -

Chiller

In the refrigeration industry, it is divided into air-cooled chillers and water-cooled chillers. According to the compressor, it is divided into screw chillers, scroll chillers, and centrifugal chillers. In terms of temperature control, it is divided into low-temperature industrial chiller and no...Read more -

small chiller

small chiller A small chiller is a cooling water device that can provide constant temperature, constant flow, and constant pressure. The working principle of the small chiller is to inject a certain amount of water into the water tank inside the machine, cool the water through the refrigeration s...Read more -

What are the various metallization processes?

What are the various metallization processes? Typically, the metallization process involves sandblasting the surface to remove blemishes and defects, followed by heating to produce molten particles that are sprayed onto the surface. Contact with a surface causes the particles to flatten and freez...Read more -

What are the benefits of the metallization process?

The many benefits offered by the metallization process include: Enhanced Corrosion Protection – Rust is a common problem when working with most metals, especially steel. Metallization creates a protective coating that inhibits the formation of red and/or white rust, extending the life of t...Read more -

cellophane

Cellophane is the oldest clear packaging product used to wrap cookies, candies and nuts. Cellophane was first marketed in the United States in 1924 and was the primary packaging film used until the 1960s. In today’s more environmentally conscious market, cellophane is making a comeback. Bec...Read more -

Bio-Oriented Nylon (BOPA)

Nylon film is a transparent film with extremely high mechanical resistance. It may absorb a certain amount of water. The higher the moisture content, the more flexible it becomes. At low moisture levels, flexibility decreases. Their excellent barrier properties help preserve the quality of the co...Read more -

Bio-Oriented Polypropylene (BOPP)

Bio-Oriented Polypropylene (BOPP) The main features of BOPP films are rigidity, high tensile strength, excellent optics and excellent waterproof properties. They range from 12 to 60 microns, more commonly 15 to 40 microns in thickness. These BOPP packaging films are co-extruded and can be clear, ...Read more -

Multilayer barrier film

Advances in barrier films have sparked a revolution in food packaging. Multilayer barrier film packaging keeps flavors inside and outside the package and provides a barrier to oxygen or other gases or moisture to ensure shelf life. APG can help design coextruded films of up to 12 layers to achiev...Read more -

Rigid sheet for thermoforming

Certain types of food require semi-rigid packaging. Thermoforming is a manufacturing process in which a sheet of plastic is heated to a temperature at which the product becomes pliable, molded into a specific shape in a mold, and then trimmed to make a usable product. When referring to thinner t...Read more -

for heat shrink labels (sleeves)

The armband is made of film that shrinks on the surface of the product when heated. This type of label allows graphics to be printed on the entire circumference of the container, as well as to take the shape of a rigid container. The eye-catching 360° graphic design makes the packaging extremely ...Read more -

heat shrinkable film

Polyolefin shrink film has excellent transparency and is a very strong biaxially oriented heat shrinkable polyolefin film. The shrinkage rate is balanced and stable during packaging. Compared with PVC film, polyolefin shrink film is soft and elastic, and will not become brittle at low temperatur...Read more -

Polyester (PET)

Polyester (PET) BOPET (Biaxially Oriented Polyethylene Terephthalate Film) has excellent physical properties and is used in a variety of products. BOPET films represent the second largest segment (by volume) in the biaxially oriented film market. In different versions of...Read more -

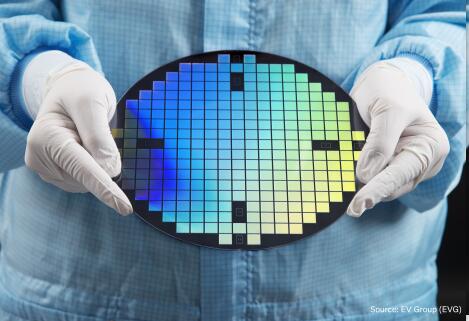

Optical Coating

Optical Coating An optical coating is a thin layer or layers of material deposited on an optical element, such as a lens or mirror, that changes the way the optical element reflects and transmits light. One type of optical coating is an anti-reflective coating, which red...Read more