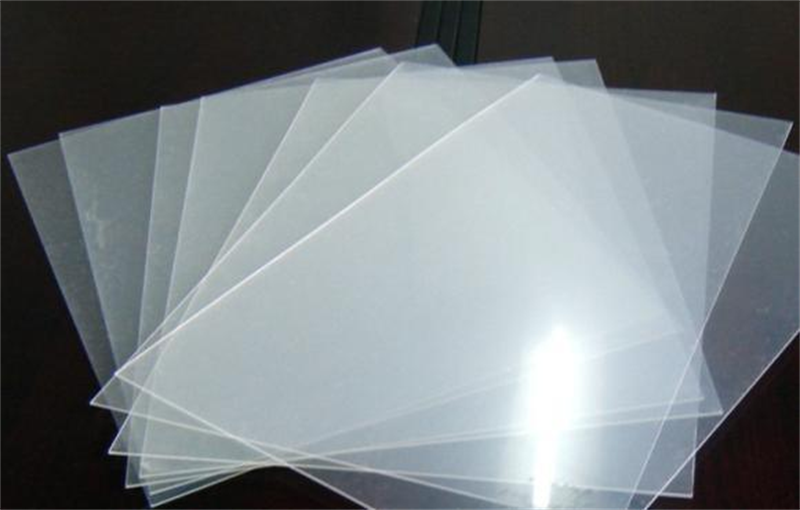

Certain types of food require semi-rigid packaging. Thermoforming is a manufacturing process in which a sheet of plastic is heated to a temperature at which the product becomes pliable, molded into a specific shape in a mold, and then trimmed to make a usable product.

When referring to thinner thicknesses and certain types of materials, the sheet or “film” is heated in an oven to a high enough temperature that it can be stretched in or on a mold and cooled to its final shape.

The materials used for thermoforming packaging are mainly PVC, PET, PP and PS.

Different options are available:

–Heat sealable –

peelable material

– Color film

– high barrier material

– Available thicknesses between 100 and 800 microns.

APG can supply semi-rigid packaging materials to meet your specific needs.

single layer

– PVC

– PET

– PP

– PS

multilayer

– PVC/PE

– PP/PE

– PET/PE

– PS/PE

High barrier properties

– PVC/PVDC

– PVC/PCTFE

– PVC/PVDC/PE

– PVC/EVOH/PE

– PET/EVOH/PE

– PP/EVOH/PP(PE)

– PS/EVOH/PE

Post time: Dec-15-2022