Polyester (PET)

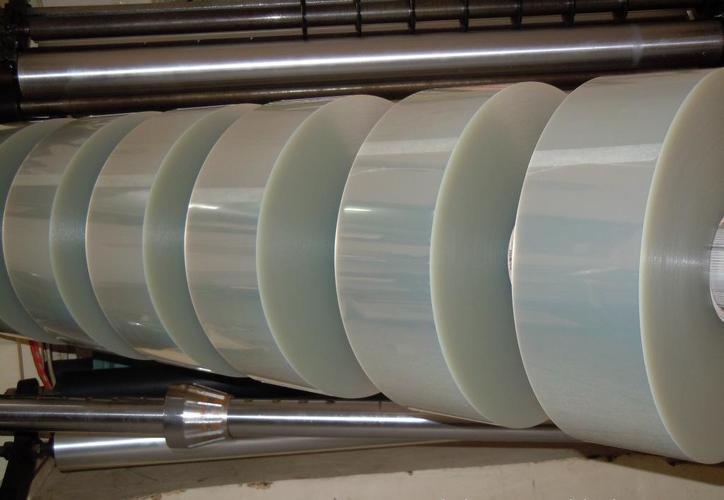

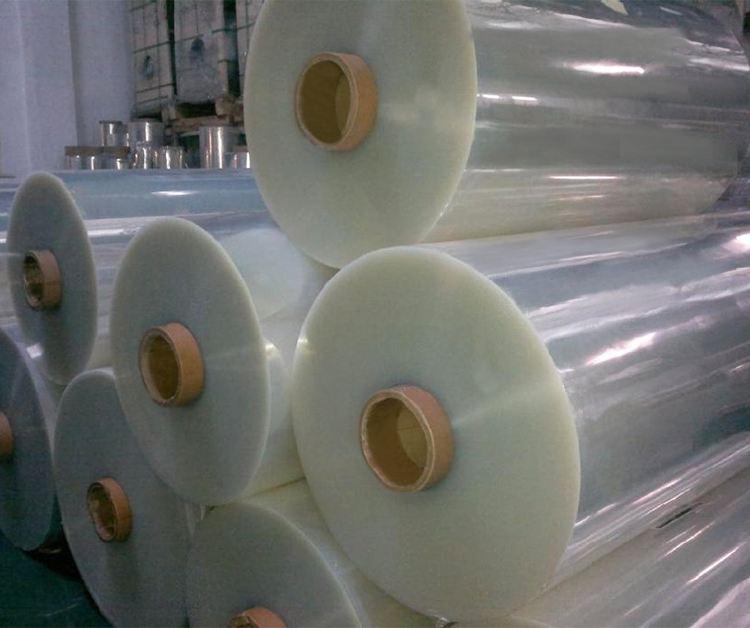

BOPET (Biaxially Oriented Polyethylene Terephthalate Film) has excellent physical properties and is used in a variety of products.

BOPET films represent the second largest segment (by volume) in the biaxially oriented film market. In different versions of BOPET films there are flat, coextruded, chemically coated, corona treated, clear, pigmented or matte films. Some applications are:

• Package

• Industrial and special applications

• Electricity

• Image

• decorate

Features and Applications:

Biaxially oriented PET (BOPET) films are successfully used in a wide range of applications due to their outstanding combination of optical, physical, mechanical, thermal and chemical properties and their unique versatility.

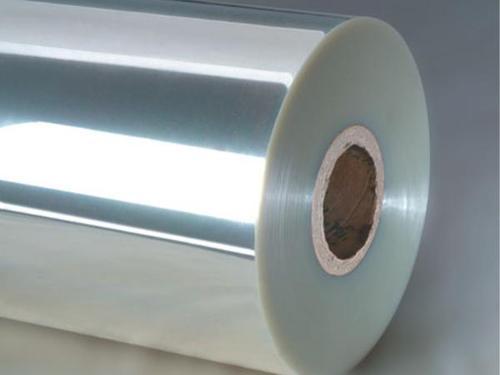

High gloss and transparent appearance

high mechanical strength

Excellent dielectric properties

Good flatness and coefficient of friction (COF)

Good tear and puncture resistance

Wide range of thicknesses - as thin as 1 micron to 350 microns

Excellent dimensional stability over a wide temperature range

Very good resistance to most common solvents, moisture, oils and greases

Excellent barrier to various gases

application:

Flexible packaging

The appeal of BOPET for flexible packaging applications is its puncture resistance, thermal stability, chemical resistance, oxygen and water vapor barrier (with surface coating), clarity; good adhesion to coatings, inks and metallization, And has non-sealing capability. Should

The material is ideal for stand-up packaging, lids, peel seals, microwave food packaging, metallization, high barrier packaging, lamination, labels, gift wrap and holographic packaging.

industry

In industry, BOPET is used as glass protective film, sheet metal protection, adhesive tape, sailing sails, thermal insulation, emergency blankets, X-ray films and visual sunscreens. BOPET has high thermal and dimensional stability to moisture, broad light transmission, high tensile strength and chemical resistance.

electric

Due to its dimensional stability, high dielectric constant and coefficient of friction, BOPET films (alone or laminated with other materials) are ideal for many electrical applications such as capacitors, motor insulation, cable barriers. As well as wire, conductor insulation wraps for solar panels, functional layers in LCD displays, speaker diaphragms and substrates for flexible printed circuit boards.

graphic design

Superior optical and surface properties and long shelf life make BOPET the material of choice for applications such as decorative panels, backlighting, roll-top banners, microfilm, blueprints and drawings, map overlays and laminates.

decorate

Due to its clarity, transparency and thermal stability, BOPET is used for decoration or numbering on textiles, paper and plastics by hot stamping and thermal transfer processes. BOPET is also used for metallized and/or decorative ribbons and confetti.

transparent -

Corona Treated Corona treated surfaces provide excellent adhesion to printing inks and laminating adhesives. The coating is directly attached to the PET surface. Recommended for general packaging applications.

Thickness options range from 8 to 50 microns.

Transparent - chemically treated

– Copolymers

Coating - Acrylic

Coatings – Special coatings for high temperature fill applications

Biaxially oriented polyester (BOPET) clear film, chemically coated on one side, provides excellent adhesion to a variety of inks and laminating adhesives.

It has a very high and stable level of surface tension over a long period of time due to the chemical coating.

Transparent - Coextrusion

Transparent biaxially oriented polyester (BOPET) film with a functional copolyester layer on one side. The modified layer has excellent compatibility with most inks, adhesives, coatings, primers, etc., and also ensures high metal bonding strength after metallization.

Thickness options from 12 to 30 microns

Clear - Coated

– PVDC coating

Metal

- corona treatment

Metallization - Chemical Treatment

Metallization - Coextrusion Copolymer Metallization -

high barrier

Metallized - Metallized High Metal Anchorage

Vacuum metallized bidirectional oriented polyester film has excellent barrier properties and high gloss. The base film used can have different options to improve the adhesion of the metal to the film.

Thickness options from 8 to 50 microns

feature

– White PET

– Matte finish

– Amber

- gold

– Flat film (untreated)

– Metallized metal polished surface

– with metallization

– Metallized matt surface

– Isotropic (metallized or not)

– cable

Film - Twisted Film (Twisted) (Metalized or Not)

-holographic

-Heat sealable

Post time: Nov-22-2022