News

-

Uses of Vacuum Coating – Manufacturing Tools

Thin film coatings are ideal for making tools because they can withstand extremely harsh conditions without pushing the tool out of tolerance. Remember, the coating is designed to be part of the tool. It’s not cosmetic, which means it won’t wear out over time or knock critical compone...Read more -

Uses of Vacuum Coating – Medical Tools

Black titanium nitride applied via PVD coating is becoming the standard for medical tools. The coating reduces friction, provides biocompatibility for implants, is antibacterial, and acts as a chemical barrier for those sensitive to nickel (usually found in tools). Not to mention, the black titan...Read more -

Protection and Performance of Vacuum Coatings

Most importantly, the critical components you use and manufacture need to be built to last. Vacuum coating technology achieves this goal. Making a part durable isn’t just about extending its life, though. It’s about maintaining a high level of performance throughout the life of that p...Read more -

Optical coatings

Optical coatings affect the ability of optical elements to transmit and/or reflect light. Thin-film optical coating deposition on optical elements can impart different behaviors, such as anti-reflection for lenses and high reflection for mirrors. Optical coating materials containing silicon and o...Read more -

optical lens

Optical lenses are optical devices designed to focus or disperse light. Optical lenses can be manufactured in a variety of shapes and can consist of a single element or form part of a multi-element compound lens system. They are used for focusing light and images, generating magnification, correc...Read more -

Vacuum coating technology

Vacuum coating technology, also known as thin-film technology, is used in a wide variety of industries, such as fresh-keeping packaging foils in the food industry, anti-corrosion protection films, solar cell production, decorative coatings for bathroom accessories and jewelry, to name a few. The ...Read more -

Plastic vacuum metallization

Plastic vacuum metallization is widely used in perfume bottle caps, car lamp reflectors, car logos and mobile phone cases all over the world. This technology is also commonly known as “PVD coating”. Compared to water-based plating, vacuum coating is a more affordable option while main...Read more -

Vacuum coating equipment market

Asia Pacific is the largest region for the vacuum coating equipment market in 2021. The regions where vacuum coating equipment is sold are Asia Pacific, Western Europe, Eastern Europe, North America, South America, Middle East and Africa. Countries where vacuum coating equipment is sold are Austr...Read more -

Uses of Vacuum Coating – Additive Manufacturing

The additive manufacturing industry is constantly evolving. New applications for 3D printing appear almost every day. The current limiting factor is the properties of the substrate used. PVD and ALD thin film coatings have the potential to enhance and improve the surface properties of additive pa...Read more -

Uses of Vacuum Coating – Automotive

Sharp brakes, corrosion, rust, rubber-to-metal adhesion problems, and overheating of engine parts… these are some of the problems that strong vacuum coatings can help with auto parts. You can coat steering column assemblies, exhaust washers, brake calipers and many other components.Read more -

Types of vacuum coating – PVD coating

Physical Vapor Deposition (PVD) is our most commonly used vacuum chamber coating process. The part to be coated is placed in a vacuum chamber. The solid metal material used as the coating is evaporated under vacuum. Atoms from the vaporized metal travel at nearly the speed of light and become emb...Read more -

Classification of vacuum coating machines

On the basis of type, the vacuum coater market is segmented into CVD (Chemical Vapor Deposition) coaters, PVD (Physical Vapor Deposition) coaters, magnetron sputtering, and others. CVD includes integrated circuits and photovoltaics, metal organic frameworks, polymerization, gas sensing, and low-k...Read more -

Vacuum Coating Equipment Market Report

The vacuum coating equipment market consists of vacuum coating equipment sold by entities (organizations, exclusive traders, and partners), which includes the application of vacuum technology, which requires sub-atmospheric pressure environments and atomic or molecular flammable vapors. Vacuum co...Read more -

UV Fused Silica Brewster Windows

UV Fused Silica Brewster Windows UV Fused Silica Brewster Window (UV Fused Silica Brewster Windows) utilizes the total reflection characteristics of the material. When the light is incident at a specific incident angle (called the Brewster angle of the material), the S-polarized component of the ...Read more -

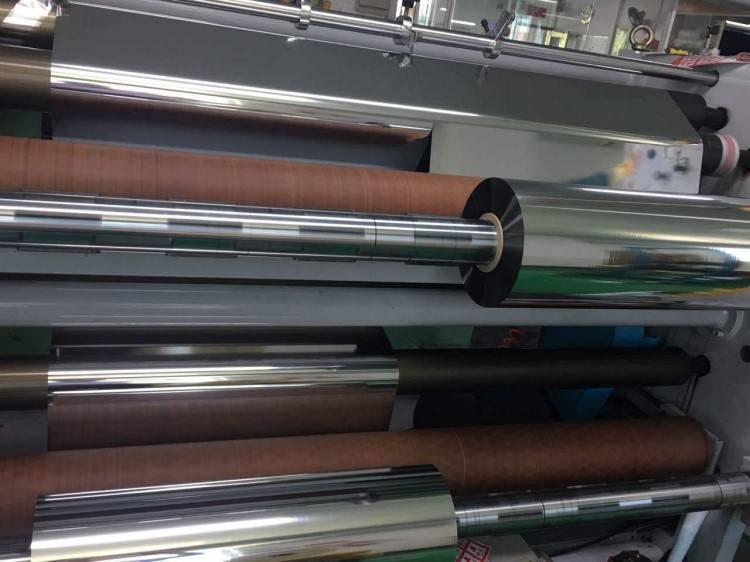

Analyze and solve common problems when using coating equipment

Coating equipment is a kind of equipment that melts and evaporates metal aluminum at high temperature in a vacuum state, so that the vapor of aluminum is deposited on the surface of the plastic film, so that the surface of the plastic film can have metallic luster. Its coating technology is used ...Read more -

aluminum foil

aluminum foil Aluminium foil is a solid sheet of aluminium of a suitable alloy, rolled to very thin thicknesses, with a minimum thickness of about 4.3 microns and a maximum thickness of about 150 microns. From a packaging and other major application point of view, One of...Read more