Various Filter Types and Key Specifications

In principle, optical filters can be divided into several types, and these different types of optical filters are introduced below.

1. Absorption filter: The absorption filter is made by mixing special dyes into resin or glass materials. According to the ability to absorb light of different wavelengths, it can play the role of filtering. Colored glass filters are the most widely used in the market. Its advantages are stable, uniform, good beam quality, and low manufacturing cost, but it has the disadvantage of relatively large passband, which is rarely lower than 30nm.

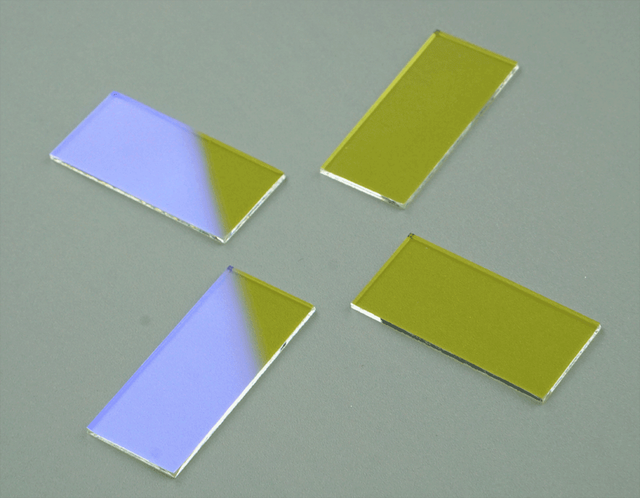

2. Interference filter: The interference filter adopts the method of vacuum coating, and a layer of optical film with a specific thickness is coated on the surface of the glass. Usually a piece of glass is made of multi-layer films, and the principle of interference is used to achieve Allows light waves in a specific spectral range to pass through. There are many types of interference filters, and their application fields are also different. Among them, the most widely used interference filters are bandpass filters, cut-off filters, and dichroic filters.

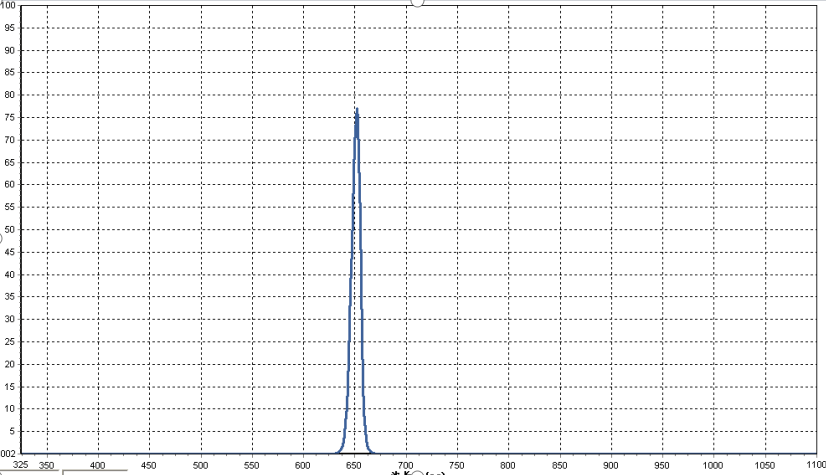

(1) Bandpass Filters can only transmit light of a specific wavelength or narrow band, and light outside the passband cannot pass through. The main optical indicators of bandpass filters are: central wavelength (CWL), half bandwidth (FWHM), and transmittance (T%). According to the size of the bandwidth, it can be divided into narrow-band filters with a bandwidth of less than 30nm; broadband filters with a bandwidth of more than 60nm.

(2) Cut-off filter (Cut-off filter) can divide the spectrum into two regions. The light in one region cannot pass through this region, which is called the cut-off region, while the light in the other region can fully pass through it, which is called the pass-band region. Typical cut-off filters are long-pass filters and short-pass filters. Long-wave pass filter: refers to a specific wavelength range, the long-wave direction is transmitted, and the short-wave direction is cut-off, which plays the role of isolating short-wave. Short-wave pass filter: Short-wave pass filter refers to a specific wavelength range, the short-wave direction is transmitted, and the long-wave direction is cut-off, which plays the role of isolating long-wave.

(3) Dichroic filter (Dichroic filter) can select a small range of colors that want to pass light according to needs, and reflect other colors. There are some other types of filters: Neutral Density Filters (Neutral Density Filters), also known as attenuation films, are used to prevent strong light sources from damaging the camera’s sensor or optical components, and can absorb or reflect light that has not been absorbed. The portion of the transmitted light that uniformly reduces the transmittance in a certain portion of the spectrum.

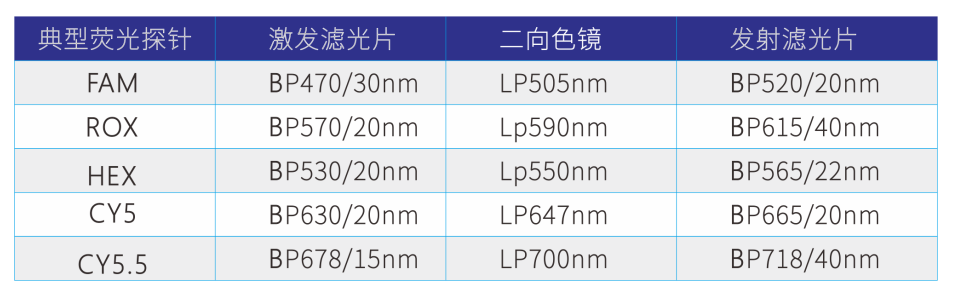

The main function of Fluorescence Filters is to separate and select the characteristic band spectra of the excitation light and emitted fluorescence of substances in the biomedical fluorescence inspection and analysis system. It is a key component used in biomedical and life science instruments.

Astronomy Filters are a kind of filter used to reduce the influence of light pollution on photo quality during the process of taking astronomical photos.

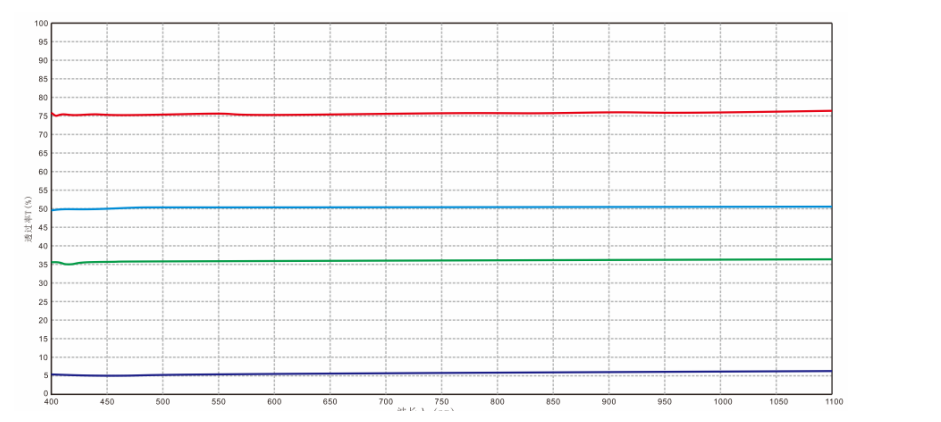

Neutral density filters are generally divided into absorptive and reflective. The reflective neutral density filter adopts the principle of thin film interference to transmit part of the light and reflect the other part of the light (usually no longer use these reflected light), these reflected light is easy to form stray light and reduce the experimental accuracy, so Please use the ABC series light collector to collect the reflected light. Absorptive neutral density filters generally refer to the material itself or after some elements are mixed in the material, which absorb some specific wavelengths of light, but have no or little effect on other wavelengths of light. Generally, the damage threshold of absorbing neutral density filters is lower, and after long-term use, there may be heat generation, so care should be taken when using them.

Key Specifications for Optical Filters

Passband: The range of wavelengths that light can pass through is called the passband.

Bandwidth (FWHM): Bandwidth is a wavelength range used to represent a specific part of the spectrum passing through the filter through incident energy, expressed by the width at half of the greater transmittance, also known as half width, in nm. For example: the peak transmittance of the filter is 80%, then 1/2 is 40%, and the left and right wavelengths corresponding to 40% are 700nm and 750nm, and the half bandwidth is 50nm. Those with a half-width less than 20nm are called narrow-band filters, and those with a half-width greater than 20nm are called band-pass filters or wide-band pass filters.

Center wavelength (CWL): Refers to the peak transmission wavelength of a bandpass or narrowband filter, or the peak reflection wavelength of a bandstop filter, the midpoint between the 1/2 wavelength of the peak transmittance, that is, the bandwidth The midpoint of is called the central wavelength.

Transmittance (T): It refers to the passing ability of the target band, expressed in percentage, for example: the filter peak transmittance (Tp) > 80%, refers to the light that can pass through the filter after attenuation. When the maximum value is above 80%, the greater the transmittance, the better the light transmission ability. Cut-off range: It is used to represent the wavelength interval of the energy spectral region lost by the filter, that is, the wavelength range outside the passband. Cut-off rate (Block): The transmittance corresponding to the wavelength in the cut-off range, also known as The cut-off depth is used to describe the cut-off degree of the filter. It is impossible for the light transmittance to reach 0. Only by making the transmittance of the filter close to zero can the unwanted spectrum be better cut off. The cut-off rate can be measured by transmittance, and can also be expressed by optical density (OD). The conversion relationship between it and transmittance (T) is as follows: OD=log10(1/T) Transition band width: according to the filter The cut-off depth is different, and the greater spectral width allowed between the specified filter cut-off depth and the 1/2 position of the transmittance peak. Edge steepness: ie [(λT80-λT10)/λT10] *

High Reflectance (HR): Most of the light passing through the filter is reflected.

High transmittance (HT): The transmittance is high, and the energy loss of light passing through the filter is very small. Angle of incidence: The angle between the incident light and the normal of the filter surface is called the angle of incidence. When the light is incident vertically, the angle of incidence is 0°.

Effective aperture: The physical area that can be effectively used in optical devices is called the effective aperture, which is usually similar to the appearance size of the filter, concentric, and slightly smaller in size. Start wavelength: The start wavelength refers to the wavelength corresponding to when the transmittance increases to 1/2 of the peak in the long-wave pass filter, and sometimes it can be defined as 5% or 10% of the peak in the band-pass filter The wavelength corresponding to the transmittance.

Cut-off wavelength: The cut-off wavelength refers to the wavelength corresponding to when the transmittance in the short-wave pass filter is reduced to 1/2 of the peak value. In the band-pass filter, it can sometimes be defined as a peak transmittance of 5% or 10%. The wavelength corresponding to the pass rate.

Surface Specifications and Dimensional Parameters of Filters Surface Quality

The surface quality of the filter mainly has defects such as scratches and pits on the surface. The most commonly used specifications for surface quality are scratches and pits specified by MIL-PRF-13830B. The name of the pits is Calculated by dividing the pit diameter in microns by 10, usually the scratch pit specification will be called standard quality in the range of 80 to 50; the quality in the range of 60 to 40; and the range of 20 to 10 will be considered high precision quality.

Surface quality: Surface quality is a measure of surface accuracy. It is used to measure the deviation of planes such as mirrors, windows, prisms or flat mirrors. The deviation of smoothness is usually measured by the corrugation value (λ), which is It is composed of test sources with multiple wavelengths, one stripe corresponds to 1/2 wavelength, and the smoothness is 1λ, which represents the general quality level; the smoothness is λ/4, which represents the quality level; the smoothness is λ/20, represents a high-precision quality level.

Tolerance: The tolerance of the filter is mainly on the center wavelength and half-bandwidth, so the tolerance range of the filter product is indicated.

Diameter tolerance: In general, the influence of the tolerance of the filter diameter is not great during use, but if the optical device is to be mounted on the holder, the diameter tolerance must be considered. Usually, the tolerance of diameter in (±0.1 mm) is called general quality, (±0.05 mm) is called precision quality, and (±0.01 mm) is called high quality.

Center Thickness Tolerance: The center thickness is the thickness of the center part of the filter. Usually, the tolerance of center thickness (±0.2mm) is called general quality, (±0.05mm) is called precision quality, and (±0.01mm) is called high quality.

Post time: Mar-10-2023